In people's daily lives, they are inevitably exposed to microorganisms, and many daily necessities are a good place for these microorganisms to survive and are also the source of the spread of some diseases. For example, bacteria can cause inflammation, infection and other symptoms. After antibacterial treatment of items: First, it protects product users, prevents related diseases caused by bacteria on the products, and improves the quality of life. The second is to prevent bacteria from multiplying and metabolizing to produce odor. The third is to improve the functionality of the product and increase the value of the product. With the improvement of the quality of life, antibacterial functional products have attracted more and more attention from people.

ANTIBACTERIAL SOLUTIONS

Textile antibacterial (test methods GB/T20944, AATCC100, ASTME2149, JISL1902, etc.)

①Add 2% antibacterial agent AEM5700 during fabric finishing for antibacterial processing;

② Or use an aqueous solution with a 5% antibacterial agent ratio to be sprayed directly onto the fabric for antibacterial processing.

Plastic or bamboo wood plastic antibacterial (test method IS022196, ASTM E2149, etc.)

①Plastics, according to different plastic types, our company has corresponding antibacterial masterbatch, and 1%-2% antibacterial masterbatch can be added for antibacterial processing.

②) Or directly add 0.3%-0.8% antibacterial agent for antibacterial processing. It is mostly used for antibacterial treatment on the surface of plastics, bamboo and wood plastics (test method 1S0 22196, etc.). For smooth surfaces, you can spray alcohol directly on the surface. An antibacterial agent that is resistant to washability and friction is attached to the surface to form a thin layer for antibacterial processing. It can be used for antibacterial stainless steel products.

Antibacterial coating (test method GB/T 21866, 1S022196)

Just add the antibacterial agent directly to the paint. For example, some products that can be used as a paint layer can be used this way.

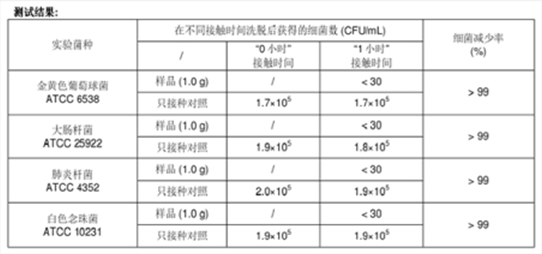

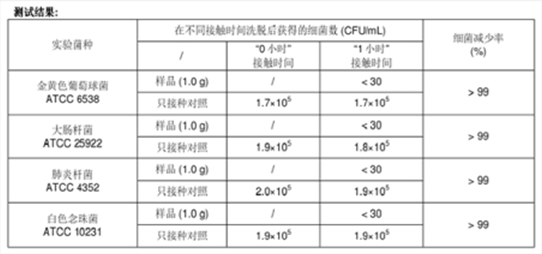

As shown in the picture below, it is used on plastic surfaces for antibacterial use and its antibacterial effect is tested.