Now more and more furniture companies are beginning to pay attention to mold and moisture prevention. Why has mold been eroding corporate profits crazily in recent years?

Based on the manufacturing process of upholstered furniture and the production process of the factory, our company has conducted research and analysis on the mold growth factors in materials, production, packaging, warehousing, and transportation of many furniture mold cases.

The causes of mildew on furniture were discovered:

1. Furniture materials are rich in food for mold growth, such as protein, starch, oil, and cellulose in bamboo and wood fibers, and collagen, protein, and fat in leather, which provide sufficient nutrients for the growth and reproduction of mold.

2. The environmental protection department vigorously promotes the use of environmentally friendly glue, and the starch in the glue has also become a food source for mold.

3. There is no suitable method to control the humidity of materials and the relative humidity of the air, which increases the risk of mildew.

4. The European Union strictly restricts the use of highly hazardous preservatives such as pesticides, DMF, and azo heavy metals. Many manufacturers cannot find effective alternatives to environmentally friendly fungicides.

5. The transportation and storage cycle is too long, making the products more susceptible to moisture and increasing the risk of mildew.

In the work of preventing mildew and moisture, the simplest and most basic way is: the desiccant absorbs moisture. Why does the product need to be moisture-proof after shipment?

In a specific package, there are three sources of moisture. The mission of the desiccant is to absorb these three parts of water vapor and control the humidity in the package within a safe humidity.

1. When the product is packaged, the initial moisture contained in the air inside the package. For example, if the volume of product packaging is 1 cubic meter, the initial temperature during packaging is 23°C, and the relative humidity is 85%, the air contains 17.47 grams of water.

2. The moisture contained in the packaging accessories in the product packaging will gradually evaporate during storage and transportation. For example, wood usually has a moisture content of 12%-20%.

3. During storage and transportation, water vapor penetrates into product packaging through barrier packaging. Then, if these three parts of water vapor are absorbed by the product, it will increase the risk of mildew. Therefore, in the actual production and packaging process, factories will use water-absorbing and moisture-proof products to absorb excess moisture in materials and air.

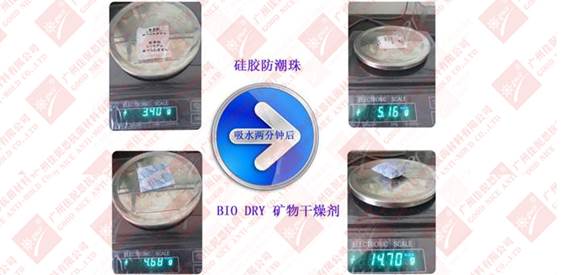

Demonstration of the actual water absorption effect of our BioDry mineral desiccant:

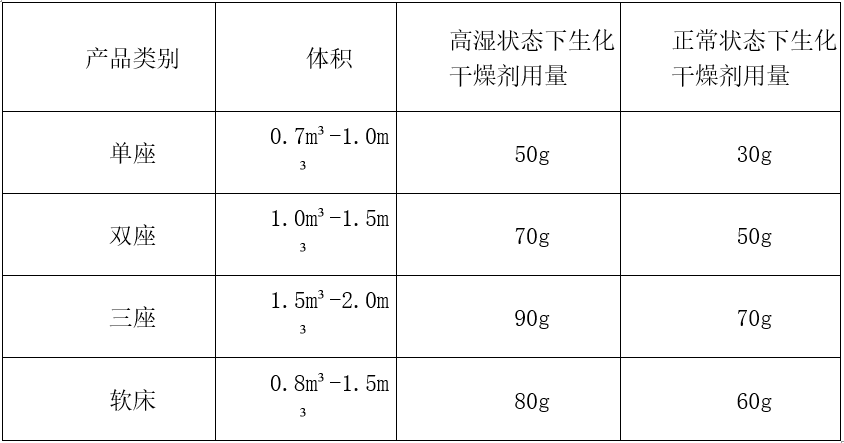

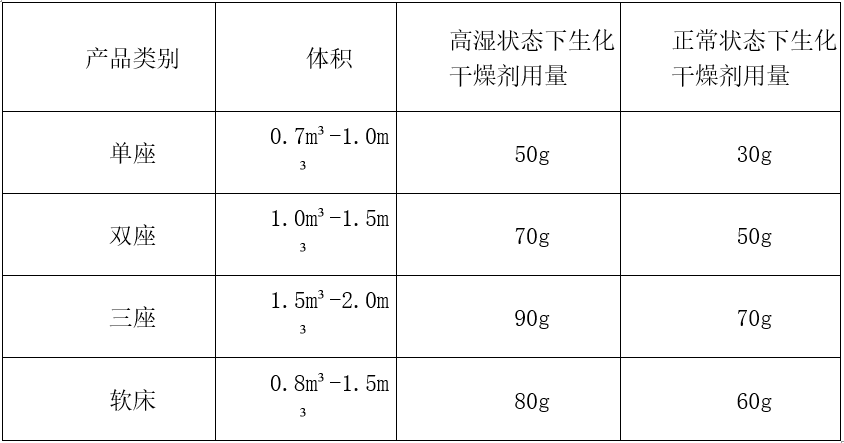

3. Process suggestions for using desiccant on upholstered furniture:

A. During the production process of the wooden frame, a certain amount of desiccant is nailed to the wooden frame to control the humidity of the wooden frame.

B. Put a desiccant into the finished furniture packaging to control the product humidity and the relative humidity of the air in the entire packaging space.