Plastic antibacterial agent AEM5700-MB is a compound of organic antibacterial agents. It has the advantages of strong bactericidal power, strong heat resistance, persistence and immediate effect, and abandons the poor safety, high temperature intolerance and easy migration of most single antibacterial agents. , the disadvantage of large dosage, and has excellent anti-mildew effect. AEM5700-MB will impart a superior and durable antibacterial film to the treated substrate and have a unique protective function against microorganisms.

Click on the image below to view product details

Features:

1. Plastic antibacterial agent AEM5700-MB has broad-spectrum antibacterial properties: it has a very broad antibacterial effect, has obvious antibacterial effects on hundreds of bacteria, and has excellent inhibitory and killing effects on common molds. It has obvious advantages compared with general antibacterial agents that are only effective against several types of bacteria;

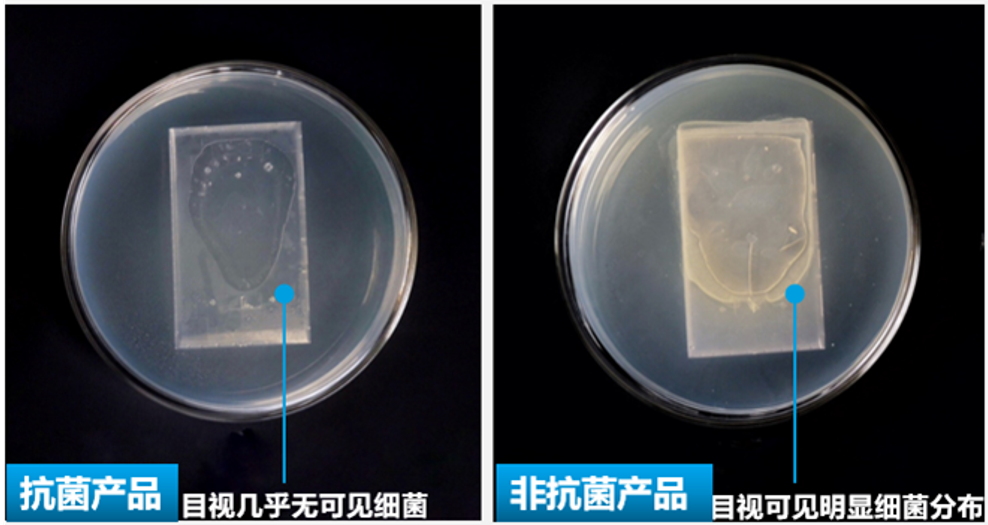

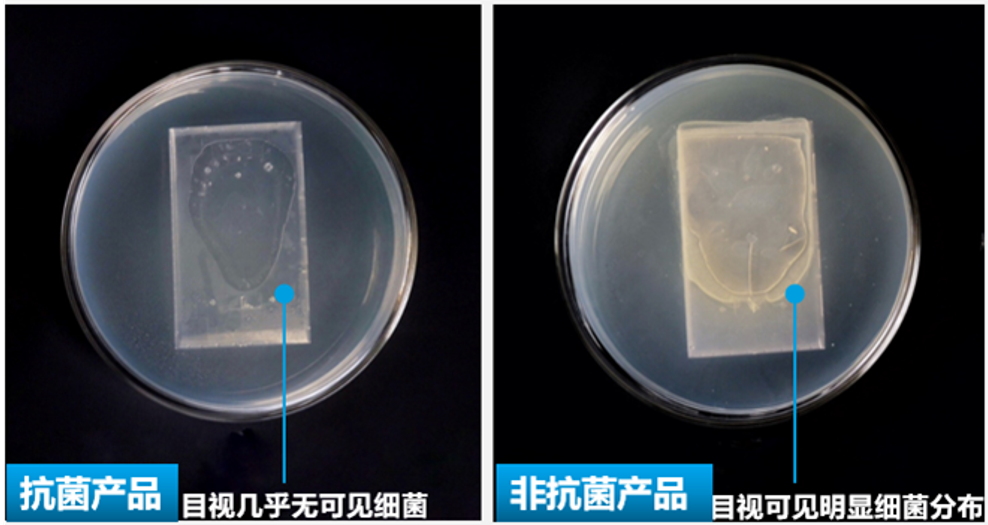

2. The plastic antibacterial agent AEM5700-MB has high antibacterial efficiency: The treated materials treated with the plastic antibacterial agent have high antibacterial rates against various microorganisms such as Staphylococcus aureus, Pseudomonas aeruginosa, Escherichia coli, Aspergillus niger, Aspergillus flavus and Trichoderma viride. Up to 99%;

3. The plastic antibacterial agent AEM5700-MB has a long-lasting effect: Generally, inorganic antibacterial agents release ions too quickly in the initial stage and have a short sterilization period. AEM5700-MB plastic antibacterial agent is not easy to hydrolyze and is a sustained-release antibacterial agent. It slows down the release of antibacterial ingredients through the function of the sustained-release agent, thereby achieving sustained antibacterial effects;

4. Plastic antibacterial agent AEM5700-MB has good thermal stability, high temperature resistance, and its decomposition temperature is less than 300°C;

5. Plastic antibacterial agent AEM5700-MB is very convenient to store, transport and use;

6. The plastic antibacterial agent AEM5700-MB is non-toxic: the acute oral LD50 for rats is 4000mg/kg, and the acute transdermal dose is 21 days. No irritation was found when the treatment dose was 250mg/kg. It is slightly irritating to the eyes. No skin irritation. Its safety is recognized by the US FDA and EPA.

Instructions:

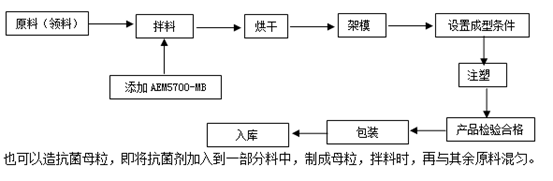

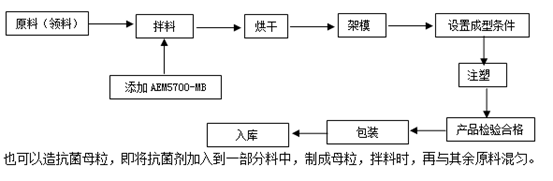

Add directly, the usage ratio is 0.5%~1%, and can be used at temperatures less than 300℃. The following is an industrial flow chart of injection molding: