1. The causes of paint mold growth usually include factors such as high environmental humidity, poor ventilation, dry storage environment, residual organic matter, and insufficient light. In a high-humidity environment, the paint surface easily absorbs moisture, providing conditions for the growth of mold;

According to our company’s experimental research and analysis on most boards and paints, combined with our company’s experience in anti-mildew technology:

2.2 Strengthen environmental control

2.2.1 During the product production process, it is necessary to strengthen the control of pollutants in the product production environment and reduce suspended solids in the air. Necessary anti-static measures can be taken to reduce the accumulation of suspended solids on the product; production equipment and production equipment must be regularly inspected. Whether the environmental drainage facilities are intact to prevent products from getting damp; formulate production operation specifications and strictly implement regular and irregular cleaning systems.

2.2.2 During the product storage process, the temperature and humidity of the warehouse need to be reasonably monitored and equipped with a good ventilation and drying system. If the warehouse will be affected by the structure and layout, the ventilation capacity is limited, and the moisture is difficult to dissipate, ventilation facilities should be added or even Place a reasonable desiccant to absorb moisture and reduce humidity.

2.2.3 Disinfection of warehouse

(1) Ultraviolet disinfection (currently the most cost-effective, environmentally friendly and safe disinfection method)

a Control the warehouse temperature below 30°C (optimal);

b Control the relative humidity below 65%;

c The installed ultraviolet lamp needs to be selected according to needs to achieve the purpose of penetrating the air layer, drying the air, and inhibiting the reproduction of mold.

d. Ultraviolet exposure: It is recommended to use ultraviolet lamps with a 185nm spectrum line (commonly known as the ozone spectrum line), which are evenly distributed on the warehouse ceiling (one every 5m). From March to July, they are turned on twice a day at night, 1.5 times each time. -2h. Usually turn it on twice a day at night, 30 minutes each time

e. Ultraviolet rays are only suitable for sterilizing the surface of materials or the air. The penetrating power is weak. It is difficult to penetrate opaque materials or thin glass, and there will be many blind spots that cannot be irradiated.

(2) Antifungal agents prevent mold growth

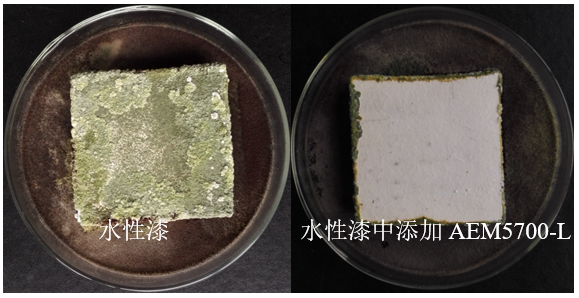

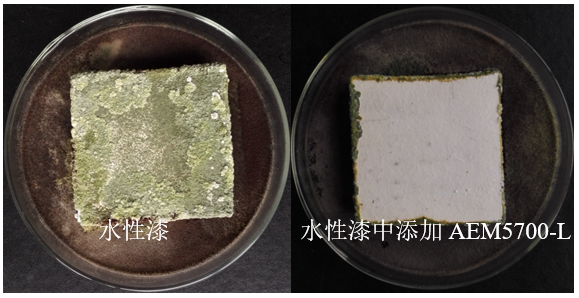

1% water-based antifungal agent AEM5700-L can be added to water-based paint for a long time;

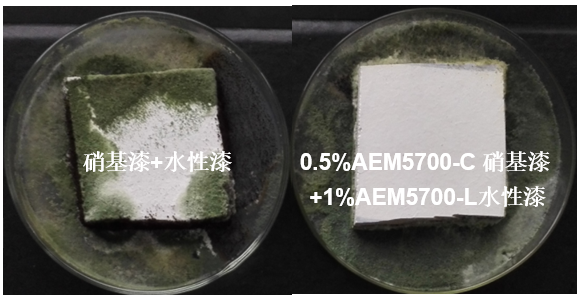

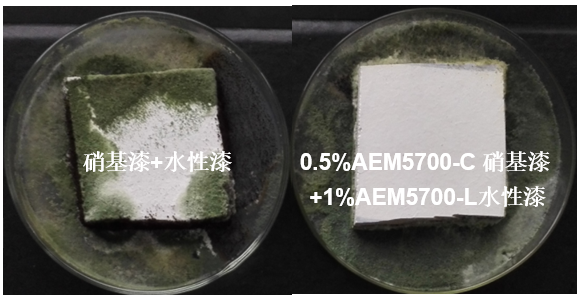

For seasons that are relatively prone to mildew or when facing harsher environmental conditions, 0.5% paint anti-mildew agent AEM5700-C can be added to the paint at the same time.

The details are as follows: 1. Add 1% water-based antifungal agent AEM5700-L, and the test results are as follows

2. If you need to deal with periods of harsh environmental conditions, you can add 0.5% paint antifungal agent AEM5700-C to the paint at the same time. The effect is as follows:

This solution belongs to the anti-mildew modification of raw materials (water-based or oil-based anti-mildew agents, suitable for the processing of product raw materials). Through the addition process, the raw materials as a whole have anti-mildew and antibacterial functions, making both the surface and the interior sterile.

The above plan is formulated based on the actual mold risk of your company's products. Strictly following this plan will completely solve your company's mold problem. It can completely protect your company's products from mold.